Low Cost with high accuracy CHMT36VB (58 feeders) Desktop SMT Pick and Place Machine

with external PC control, 0402-5050, SOP, QNF, TQFP... Updated from chmt36va

Very good for small batch production, low volume production, protopyting, researching, eduction etc.

Introduction:

1. Model number: CHM-T36VB

2. Brand: Charmhigh

3. Main configuration: Benchtop type + Two vision cameras + 2 Heads 58 tape feeders + External PC control + Closed-loop control motor with encoder

4. Max PCB area: 345*360mm

5. Component: 0402-5050, SOP, QFN, QFP, BGA etc.

6. Dimension: 1310mm(L)×710mm(W)×340mm(H), AC220V/110V (50/60Hz)

7. Lead time: 1-3 working days (In stock)

8. Delivery: by DHL express door to door, total takes 5-8 days.

9. Payment method: Aliexpress, wire transfer (T/T); PayPal; credit card; W/U

10. Packing: plywood box

11. HS code: for USA: 8479.89.92.00

For EU: 8479897000 (Pick and place machine)

Best seller- CHM-T36VA discount price $3850 USD DHL free shipping!

Machine in stock, fast ship , fast delivery, whole time around 6-9 days to your place.

Machine is completed set, ready to use as long as you prepare a computer which has USB port. We suggest windows 7 or windows 10 system.

Machine will be 100% tested well before ship out. Please purcahse in confidence.

Specifications:

Model | CHM-T36VB |

PCB area | 10mm*10mm - 345mm*360mm |

X Y axis Travel | 400*460mm |

Z axis moving range | 15mm (Highest component 5mm) |

Placement heads | 2pcs (comes with 4 nozzles) |

Feeders | Tape feeders left side total 29pcs: (8mm=44pcs, 12mm=8pcs, 16mm=4pcs, 24mm=2pcs) Tube feeder supported (optional) |

Vision system | Two cameras (up & down camera) Vision max range 22*22mm |

Drive | Closed-loop control stepper servo drive system, with encoder, not out of step |

Z axis self-return detection | Yes, it prevent nozzles breaking |

Pull needle self-return | Yes, it prents needle break |

Leakage of material | Vacuum detection, vision detection |

Mounting speed | 2500cph (vision on) |

Mounting precision | ±0.025mm |

Components | 0402-5050,SOP,QFN, QFP etc. |

Machine dimension | L 1310mm * W 710mm * H 340mm |

Vacuum pump | -92KPA (2pcs,build-in, mute type) |

External air source | No need (machine build-in mute vacuum pump 2pcs) |

External PC | Yes (software compatible with windows7, windows10) |

Voltage | 110VAC/ 220VAC, 50Hz/60Hz |

Net weight | 55kg |

Gross weight | 80kg |

Description:

The CHMT36VB is updated from chmt36va which added right side 29pcs feeders, total 58pcs feeders, it can install more different kinds of tape. It is a low cost good accuracy two heads desktop sized pick and place machine from Charmhigh. You can use it to produce a variety of designs, 50 to 100pcs at a shot. It works very well for low-volume high-mix pick and place of 0402 based designs.

CHMT36VA is a vision-based desktop pick and place machine which need to connect external PC with windows 7/10 system.

It is very reliable with low-cost economic model, this small platform machine comes with advance vision system, closed-loop control, high precision and easy operation software.

It compatible with all different kinds of components 0402-5050,SOP, QFN, QFP... very suitable for for prototype builders, hobbyists, developers, and development groups and small batches production, you just need to prepare a computer which has USB port.

CHMT36VB compatible software:Altium designer,Protell99SE,PADS,Kicad,Eagle,Cadint,Cadence Orcad,Cadence Allegro,PROTEUS..etc. As long as the software can generates the X.Y coordinates.

Advantages of CHMT36VB:

1. Convenient software provided by Charmhigh, install on windows 7/10 computer, learn fast and easy to operate, It only takes half a day to get started.

2. Top and bottom two vision cameras, correct the position of each components, you can view the vision image from screen for every components.(max component size 22*22mm)

3. It has flexible PCB clamping fixture, suitable for different size of PCB.

4. It supported custom IC tray, IC tray can be fixed on machine table.

5. Two mounting heads with 2pcs Juki Nozzles, Juki nozzle inside magnet, so it can be removed by finger, no need to disassemble with wrench, nozzles rotation angle -180 degree to +180 degree.

6. Z axis detection, machine's pull needle automatically return to origin to avoid nozzles broken.

7. Max height component support 5mm.

8. Closed-loop control, X,Y Axis with encoder, not out of step.

9. PCB calibrated by two components position, then rest components will be calibrated automatically.

10. With vacuum detection, with automatic feeding, if one component suck crooked, it will automatically throw it to deposit area, then pick a new one to mount again.

11. With vision detection, camera will auto correction component angle and place on PCB board right place.

If heads not picking up components, camera will detect it and go back to pick again, 3 times not picking, machine will alarm and stop, after supply material, then continue working, no need to start over again.

12. Comes with convert tool (PC version), edit work file in computer and load work file into machine by USB port, quick and convenient.

13. Support panelized boards.

14. If you don't have PCB file, you can create a new work file to program in machine directly.

15. Support single step.

16. Support cut tapes/ bulk material/ tube material.

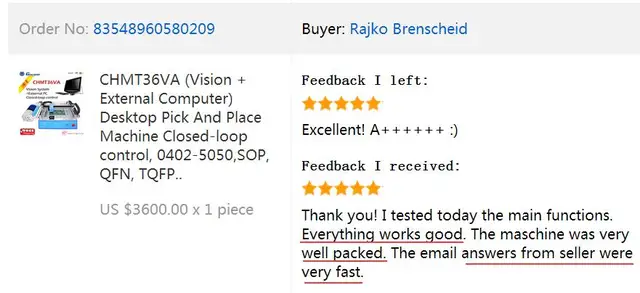

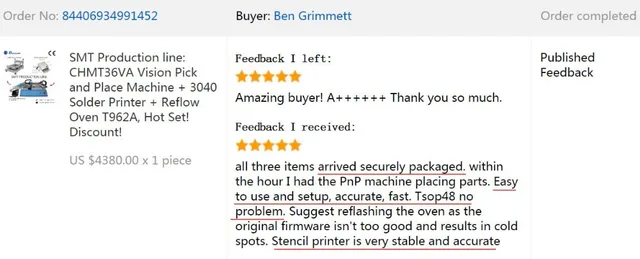

100% high feedback from customers:

This is CHMT36VA (left 29pcs feeders), it is our most popular model with perfect performace:

This is CHMT36VB, added right side 29 more feeders:

Machine got 2 heads work with high quality Juki Nozzle:

A closed-loop servo high-pressure stepper motor system, ensure never loose steps:

Custom IC tray supported:

PCB Samples produced by customers:

Cut tape supported:

Software of Charmhigh:

Real picture of CHMT36VB:

Strong packing:

Kindly note:

The CHMT36VB pick and place machine is complete set with all accessories included in the package, QC passed. You need to prepare a computer before start the machine.

We provide timely after-sales service, each machine 100% tested well before ship out. Please purchase it with confidence.

Enjoy with your pick and place machine!

Service & Warranty:

The complete machine has a warranty period of 1 year from the time of purchase and lifetime service.

We always provide spare parts of machine, factory reliable direct supply.

We provide online Q/A and troubleshooting support and technical advice service.

Provide one to one after-sale service. Each machine 100% tested well before ship out.

Tech support & Contact:

Kimi Liu

Charmhigh Technology Limited

Mob/ WhatsApp: 0086 135 106 75756

Skype: kimiliu89

E-mail:kimi@charmhigh-tech.com

Welcome to follow us on YouTube: www.youtube.com/c/KimiLiuCharmhigh/videos

If you want to see more information and videos, please contact us by E-mail.

We will response you at the first time.